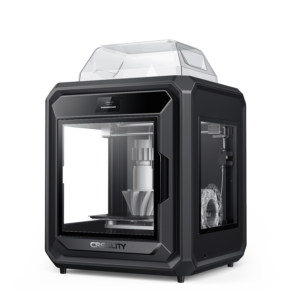

Raise3D E2CF 3D Printer

4793,80 € VAT Excl.

The Raise3D E2CF, an IDEX 3D printer, is meticulously engineered for optimal printing with carbon fiber-reinforced filaments, including PA12 CF, PPA CF, and PPA GF, among others. This compact desktop 3D printer is a standout choice for manufacturing, prototyping, and other applications. Carbon fiber-reinforced filament is recognized for its exceptional properties: low density, high strength, resistance to corrosion, static electricity, and capability to withstand high temperatures. These characteristics make it highly suitable for diverse applications, especially in industries necessitating a significant strength-to-weight ratio in their solutions, such as aerospace and automotive industries. The Raise3D E2CF exemplifies durability and stability, guaranteeing precise and accurate 3D prints.

REFERENCES:

Out of stock

Properties

- Accuracy: 10 microns

- Print bed dimensions: Simple extrusion : 330 x 240 x 240 mm, Double extrusion : 295 x 240 x 240 mm

- Speed: 30 – 150 mm/s

- Compatible materials: PA12 CF, PA12 CF Support, PPA CF, PPA GF, PPA Support

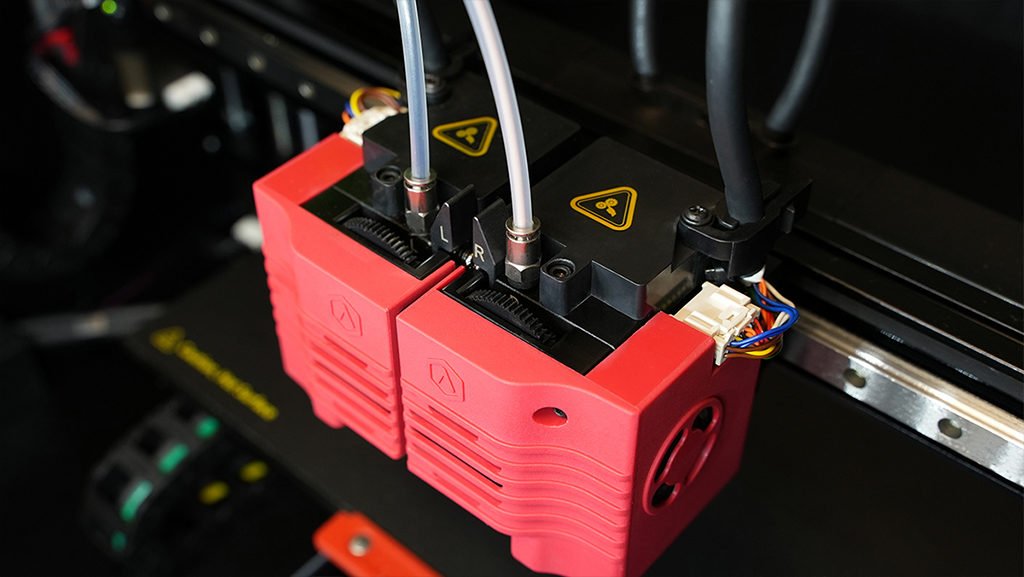

Independent double extrusion

The gears are made of high-hardness steel and have been heat-treated for improved wear resistance. With a customized gear tooth profile, the filament is held firmly in place to ensure it doesn’t slip during extrusion. The strength of the system is enhanced to ensure print stability.

Highly durable nozzles

The new silicon carbide nozzles have excellent wear resistance and thermal conductivity, which will effectively reduce the abrasion to which the carbon fiber composite filament subjects the nozzle during printing, making the nozzle more durable.

*Nozzles made from other materials suitable for printing carbon fiber filaments will be launched in the future.

Designed for printing reinforced filaments

The E2CF 3D printer works perfectly with Raise3D Industrial PA12 CF filament and support material. Raise3D Industrial PA12 CF filament is reinforced with short carbon fibers and features excellent stiffness and strength, heat resistance, low warpage, and low water absorption. Meanwhile, this material has an exceptional strength-to-weight ratio and will achieve improved mechanical properties and dimensional stability after annealing, making it suitable for replacing metal in the manufacture of certain lightweight components. In the future, more carbon fiber-reinforced filaments will be available for the E2CF 3D printer, such as Raise3D’s PPA CF, PET CF, PPS CF (with a print temperature between 280 and 300 ºC). In addition, third-party filaments certified by the Raise3D Open Filament program, such as BASF and LEHVOSS, will be available for the E2CF at a later date. The 3D printer supports only authorized filaments and print profiles. For the full list, please consult the datasheet or contact Raise3D.

Video-assisted offset calibration

The calibration system guides users through a simple video-based process to verify that the E2 is geometrically aligned. After completing the offset calibration guide, the Raise3D E2 can be used without worry, with correctly aligned extruders.

Save and resume printing

Power loss recovery allows users to print without worry. The system automatically stores print progress before a power failure and resumes from the most recent job once power is restored.

End-of-filament sensor

Reliable and precise optical end-of-filament sensors automatically interrupt printing when the printer runs out of filament. When the filament runs out, a red light flashes and printing is interrupted. Users can then simply add filament and press Resume. All types of filament can be detected, regardless of color, material or hardness.

ideaMaker software

Prepare 3D files for 3D printing with ideaMaker, the slicing software from Raise3D. Its user-friendly interface lets you prepare .STL, .OBJ and .3MF files in as little as 4 clicks, and its powerful parameters offer unlimited customization for advanced users. Designed specifically for Raise3D printers, slicing with ideaMaker is fast, efficient and free.

- Name of software: ideaMaker

- Supported files: stl, obj, 3mf

- Compatible with: Windows / Mac OS / Linux, (compatible GCODE)

| Weight | 45 kg |

|---|---|

| Dimensions | 607 × 596 × 465 mm |

| Printing Technology | FDM |

| Print dimensions | Double: 295 x 240 x 240 mm, Simple: 330 x 240 x 240 mm |

| Print speed | 30 – 150 mm/s |

| Resolution | 10 microns |

| Nozzle diameter | 0,4 mm, 0,6 mm, 0,8 mm |

| Filament diameter | 1,75 mm |

| Compatible materials | PA12 CF, PA12 CF Support, PPA CF, PPA GF, PPA Support |

| Max. extruder temperature | 300 °C |

| Max. plate temperature | 110 °C |

| Ambient operating temperature | 15 – 30 °C |

| Storage temperature | from -25 °C to +55 °C |

| Screen | 7-inch Touch Screen |

| Interface | USB/Ethernet/Wi-Fi |

| Warranty | 1 year |

| Power | 100-240V AC, 50/60Hz 230V @ 2 A, 350 W |

Reviews

There are no reviews yet.